If you’ve ever stepped outside on a January morning in Chicago, you know it’s not for the faint of heart. Frigid wind, snow-packed driveways, and below-freezing temps are just another day in the city’s longest season. So it’s understandable why the idea of starting a construction project in the dead of winter might seem unreasonable.

But what if waiting until spring isn’t an option?

With average daily highs hovering around 32°F (0 °C) in January and over 120 days per year below freezing at O’Hare, winter in the Windy City is no joke. So if you’re thinking about starting a construction project when the snow is flying, it’s completely normal to hesitate. Whether you’re planning a major remodel, an addition, or a custom build that needs to be ready by fall, the real question becomes: can it be done, and can it be done well, even when the ground is frozen solid?

Let’s understand how winter construction in Chicago works: what makes it feasible, what hurdles to expect, and how seasoned builders navigate the coldest months with precision and confidence.

How Do Chicago Winters Affect Daily Life and Infrastructure?

On average, Chicago receives around 38 inches of snow each winter, and temperatures often plunge well below freezing between late November and early March. These conditions create logistical hurdles that can slow or stall progress if not adequately addressed.

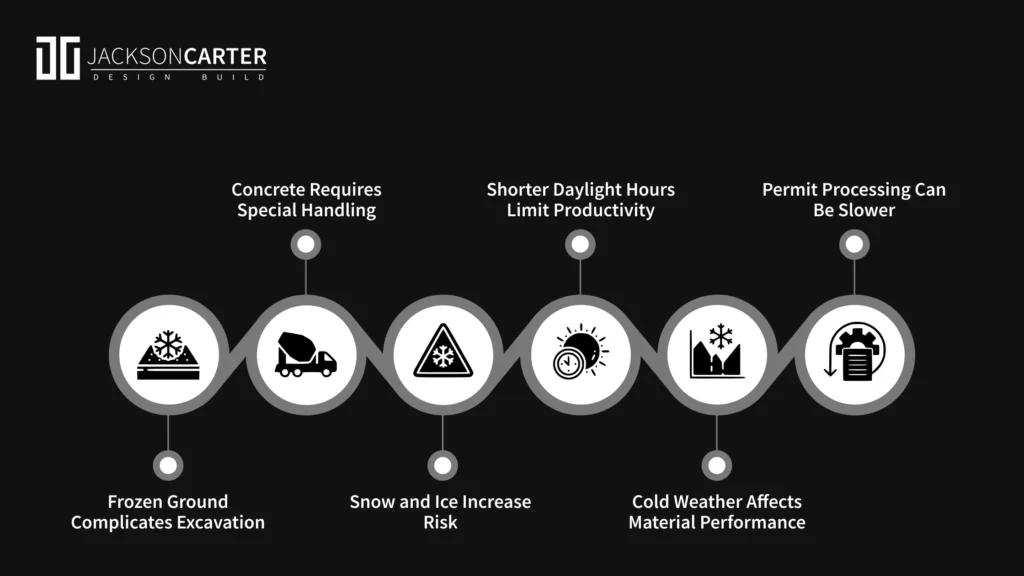

Frozen Ground Complicates Excavation

When the soil freezes, it becomes harder to dig for foundations, footings, or utility lines. This may require specialized equipment or soil heating methods to move forward safely and efficiently.

Concrete Requires Special Handling

Concrete can’t cure properly if the temperature drops below 40°F without intervention. Builders must use heated enclosures, warming blankets, or additives to ensure that strength and durability aren’t compromised.

Snow and Ice Increase Risk

Slippery surfaces and accumulated snow slow productivity and increase the risk of injuries on-site. Teams must allow extra time for clearing and implement strict safety protocols to keep workers protected.

Shorter Daylight Hours Limit Productivity

With fewer daylight hours, construction teams have a narrower window to complete outdoor tasks, making careful scheduling essential to avoid delays.

Cold Weather Affects Material Performance

Materials like adhesives, paints, and sealants may not bond or dry correctly in cold temperatures, requiring storage indoors or substitution with winter-rated products.

Permit Processing Can Be Slower

While winter may reduce competition for permits, some municipal departments operate with reduced staff or holiday closures, which can delay approvals.

Despite these challenges, winter construction is not only possible; it’s often practical with the right planning and team.

Pros and Cons of Winter Construction

Cold weather might not seem like the ideal time to break ground, but winter construction in Chicago has more to offer than most people expect. While it’s true that the season brings logistical challenges, it also opens the door to unique opportunities, especially for homeowners who plan and partner with an experienced builder.

We’ve laid out the most essential advantages and drawbacks to help you weigh the practicalities of a winter build:

| Pros | Cons |

| Greater Contractor Availability | Frozen Ground & Delays |

| Faster Permitting | Concrete Curing Risks |

| Potential Cost Savings | Weather Interruptions |

| Dryer Ground Conditions | Worker Comfort & Safety |

| Quicker Project Start | Material Performance Issues |

Top 6 Successful Winter Construction Strategies

While weather conditions introduce additional complexity, a combination of advanced planning, specialised equipment, and modified workflows can ensure continuity and quality throughout the build.

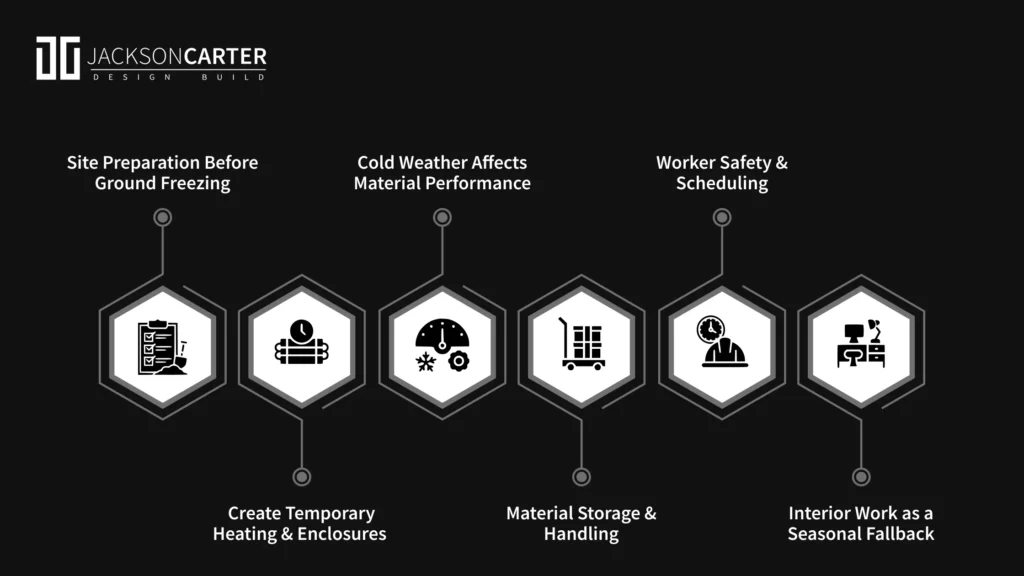

1. Site Preparation Before Ground Freezing

One of the most essential steps for successful winter construction is completing critical site preparation before the ground freezes.

Early site prep typically begins with clearing vegetation, removing topsoil, and levelling the terrain. If excavation is required for basements, footings, or crawlspaces, completing this before the frost line sets in (typically mid to late November in the Chicago area) can help avoid the need for costly ground-thawing equipment later on.

During pre-winter preparation, winter construction companies in Chicago often complete the following tasks:

- Excavation for Foundations: Digging and backfilling before frost ensures structural elements aren’t delayed

- Trenching for Utilities: Water, sewer, and electrical lines are installed early to avoid frozen pipework or delays in inspections.

- Gravel Base Installation: A compacted gravel layer helps manage moisture and prevent soil heaving.

- Access Road Stabilisation: Temporary gravel or mats are laid to maintain equipment access and avoid muddy, impassable conditions

- Drainage Setup: Ditches, temporary culverts, or sump systems help redirect snowmelt and rain away from the foundation area

- Ground Covering: Frost blankets or erosion control mats are used to protect open areas from hard freezing.

Builders can maintain momentum through the winter and avoid weather-related shutdowns by addressing these critical steps in advance. Proper site preparation serves as a foundation not just for the structure itself, but for the entire cold-weather workflow that follows.

2. Create Temporary Heating & Enclosures

When temperatures drop, construction sites require controlled environments to maintain stable materials, protect ongoing work, and enable crews to continue working safely and efficiently. Temporary heating, combined with protective enclosures, plays a vital role in allowing year-round construction, especially during Chicago’s long and often unpredictable winters.

Enclosures help trap heat, block wind, and shield work areas from snow and freezing rain. These can range from simple plastic sheeting over scaffolding to fully framed and insulated temporary structures. Once enclosed, the area can be safely heated to maintain the minimum temperatures required for specific tasks, such as painting, drywall installation, and concrete curing.

Heating systems are selected based on the type and size of the enclosure. Indirect-fired heaters are commonly used because they supply clean, dry heat and are safer for enclosed spaces than direct-fired alternatives.

Major components of effective winter heating and enclosure setups include:

- Enclosure Materials: Polyethylene sheets, insulated tarps, or rigid panels are used to wrap open frames and cover exposed areas.

- Framing Systems: Lightweight metal or wood frames create temporary walls and ceilings around critical work zones

- Heaters: Indirect-fired heaters with proper ducting reduce moisture and improve air quality; electric heaters may be used for smaller enclosed areas.

- Ventilation: Fresh air intake and exhaust systems help prevent condensation and ensure safe air quality for workers.

- Thermal Monitoring: Thermostats and temperature sensors ensure heat is consistent and appropriate for materials and crew comfort.

Using temporary heating and enclosures prevents delays due to weather and helps maintain quality standards across all construction phases. Without these systems in place, adhesives might fail, finishes could crack, and the strength of the concrete could be compromised.

3. Cold-Weather Concrete Procedures

Concrete is a foundational material in almost every construction in Chicago, but winter conditions pose unique challenges to its successful placement and curing.

When temperatures drop below 40°F (4°C), the chemical reactions responsible for concrete hardening slow dramatically, increasing the risk of incomplete curing, surface scaling, or structural weaknesses. Proper cold-weather concrete procedures are essential to ensure strength and durability during winter construction.

Major strategies to manage concrete in cold weather include:

Use of Accelerating Admixtures: Chemical additives accelerate the curing process, helping concrete gain strength faster and reducing vulnerability to freezing damage.

Heating Materials Before Mixing: Using warm water and aggregates prevents the initial concrete mix temperature from dropping too low during placement.

Thermal Enclosures and Blankets: After pouring, insulating blankets or heated tents maintain the concrete’s temperature, protecting it from freezing during the critical curing period (usually the first 48–72 hours).

Continuous Temperature Monitoring: Sensors and thermometers track curing temperatures, allowing for adjustments to heating or insulation as needed.

Controlled Pour Timing: Scheduling pours during the warmest parts of the day and avoiding extremely cold or windy conditions minimizes exposure to damaging elements.

Proper Mix Design: Specifying winter-grade concrete mixes with lower water content and adjusted cement ratios improves freeze-thaw resistance and workability.

Following these procedures helps prevent common winter concrete problems such as delayed set times, surface cracks, and compromised strength. Although concreting requires more effort and monitoring, it remains a practical option when proper techniques are applied, enabling construction in winter in Chicago to proceed without sacrificing quality or safety.

4. Material Storage & Handling

Cold temperatures significantly impact the performance and usability of many construction materials, making proper storage and handling crucial during winter construction projects. Materials such as adhesives, sealants, paints, and coatings are susceptible to changes in freezing and humidity. When exposed to low temperatures, these products can thicken, separate, or lose their adhesive properties, potentially leading to failures or costly rework.

To maintain material integrity, it’s essential to store sensitive supplies in climate-controlled environments where the temperature and humidity remain within the manufacturer’s recommended ranges. On-site storage areas may include heated trailers, enclosed containers, or interior rooms that protect materials from freezing overnight or during prolonged cold spells.

Handling practices must also adapt to winter conditions. For example, materials taken out for immediate use should be allowed time to acclimate to ambient temperatures to avoid condensation and uneven application. General contractors in Chicago may also opt for winter-grade or specially formulated products to ensure reliable performance at lower temperatures, thereby guaranteeing consistent adhesion, drying, and curing.

5. Worker Safety & Scheduling

Winter construction in Chicago demands careful attention to worker safety and efficient scheduling. Cold temperatures, ice, and snow increase the risk of slips, falls, and cold-related illnesses like hypothermia or frostbite. To protect crews, employers must provide appropriate cold-weather gear, including insulated clothing, gloves, and boots, along with heated break areas to warm up safely.

Scheduling is adjusted to maximize productivity during the limited daylight hours and relatively warmer parts of the day. Outdoor tasks are prioritized earlier when conditions are more stable, while indoor or sheltered work is planned during extreme cold spells.

Regular safety briefings and site inspections ensure hazards are promptly addressed, helping maintain both worker well-being and steady project progress throughout the winter months.

6. Interior Work as a Seasonal Fallback

When outdoor conditions become too harsh for exterior construction tasks, shifting focus to interior work provides an effective way to maintain project momentum during winter. Once the building envelope is sealed, meaning the walls, roof, windows, and doors are installed, interior phases, such as electrical wiring, plumbing, drywall installation, painting, cabinetry, and flooring, can proceed largely unaffected by outdoor weather.

This shift allows Chicago home remodelers to work in controlled environments where temperature and humidity can be regulated, improving both productivity and quality. Interior work during winter also helps avoid potential supply chain delays common in peak construction seasons, as demand for materials and labor often dips in colder months.

Is Winter Construction Right for You?

Deciding whether to undertake a construction project during Chicago’s winter depends on several factors unique to your situation. If your timeline is tight and delaying work until spring isn’t feasible, construction in winter in Chicago can be a practical choice, provided you understand the challenges and plan accordingly.

Common considerations include:

- Project Scope: Structural projects may require more winter-specific adaptations than interior renovations.

- Budget: Additional costs for heating and materials might apply, but can be balanced by the availability of new home builders in Chicago and permit speed.

- Timeline Flexibility: Weather unpredictability means scheduling buffers are essential.

- Builder Experience: Chicago residential contractors skilled in winter construction in Chicago are critical for quality and safety.

Your comfort with these factors will help determine if building through winter aligns with your goals.

Plan Your Winter Build Confidently With Jackson Carter Design Build

Building in Chicago’s winter presents unique challenges, but with the right preparation, strategies, and expertise, it’s entirely possible to keep your construction project on track through the coldest months. Understanding the impacts of winter conditions and planning accordingly can help you avoid costly delays while maintaining quality and safety.

At Jackson Carter Design Build, we do more than build spaces; we guide you through every phase with clarity and care. Don’t let Chicago’s winter slow down your remodel; our streamlined process keeps things moving, even in the cold.

Here’s what sets us apart:

- Full-service team from design through construction under one roof

- Client portal with live project updates, schedules, and 3D captures

- Weekly progress meetings and transparent budgeting

- Lifestyle-aligned designs tailored to your needs and taste

- Certified professionals committed to quality and long-term value

Winter is the perfect time to plan or begin your renovation. While others hit pause, we help you get ahead, so your project is ready to shine come spring.

Explore how we can bring your winter remodel to life, without compromising on quality, budget, or timeline.